Laser cleaning machine

As a pioneering name in the realm of laser cleaning technology, we deeply comprehend the significance of simplifying operations for our esteemed clientele. Hence, we present this dedicated platform, designed to facilitate swift and trouble-free booking for your laser cleaning needs.

Empowered by cutting-edge technology and an extensive array of laser cleaning machine variants, we cater to diverse requirements of our customers. However, our commitment extends beyond merely providing superior products. We are dedicated to ensuring that the reservation process mirrors the seamlessness of our innovative solutions, delivering a comprehensive and satisfying experience for all our patrons.

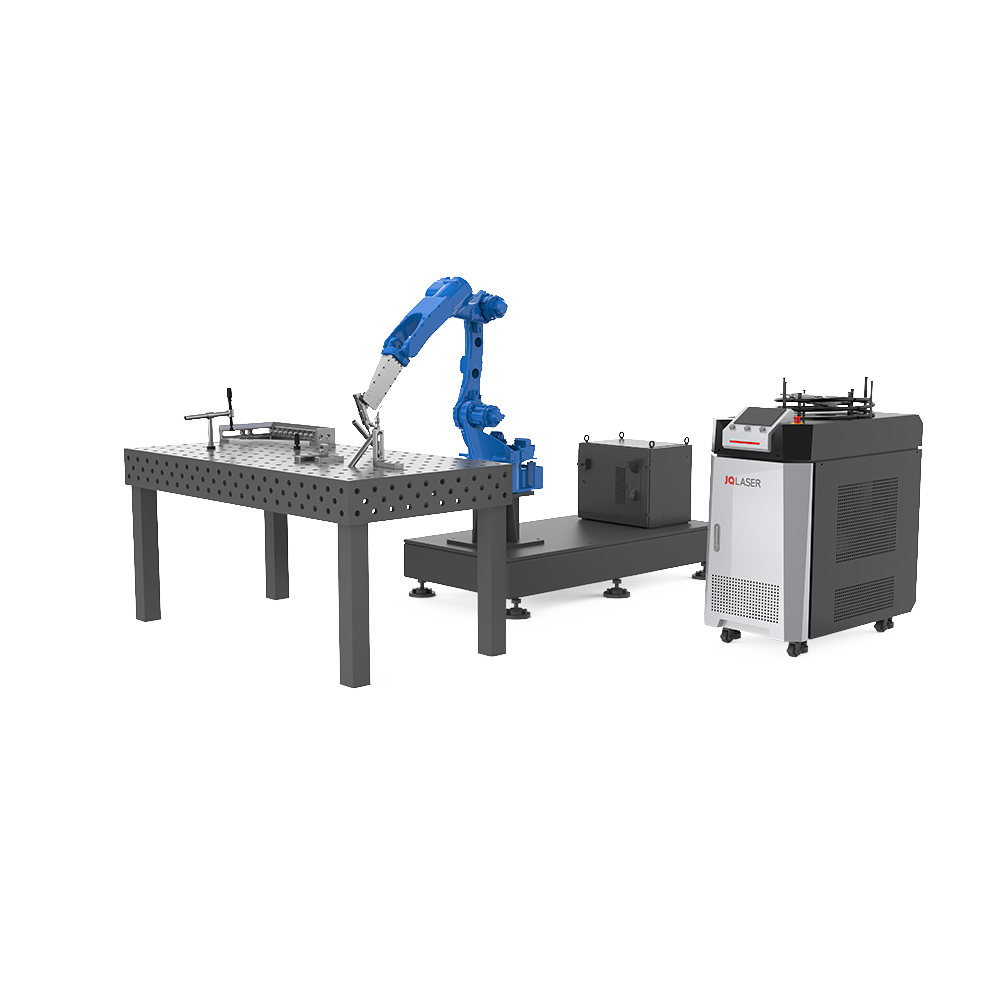

Product 3D presentation

Introduction

At JQ Laser, we synergize cutting-edge technology with profound industry expertise to fabricate top-tier laser cleaning machines that surpass the highest industry benchmarks. Our team of proficient engineers and technicians is committed to the development of state-of-the-art laser cleaning equipment that guarantees unparalleled precision, dependability, and efficiency in every application.

With an extensive spectrum of laser cleaning machines, we cater to diverse applications and industries. Whether you’re engaged in aerospace, historical restoration, or manufacturing, our machines are meticulously crafted to meet the specific demands of your projects, ensuring optimal results every time.

Basic product parameters

The values in the table below are variable and depending on the final configuration of desired model. Parameters of each device are fixed and given in commercial offers only.

| Supply voltage | 220±10% V AC 50*60Hz |

| Working temperature | 10-40℃ |

| Working environment humidity | <70% |

| Cooling method | Water cooling |

| Applicable wavelength | 1064nm(±10nm) |

| Applicable power | ≤2000W |

| Weight | SUP20C 0.8KG |

Important air circuit components

All important gas circuit components are imported components, and the entire gas circuit system adopts high-pressure resistant design to ensure the stability of the system and improve the reliability of the machine.

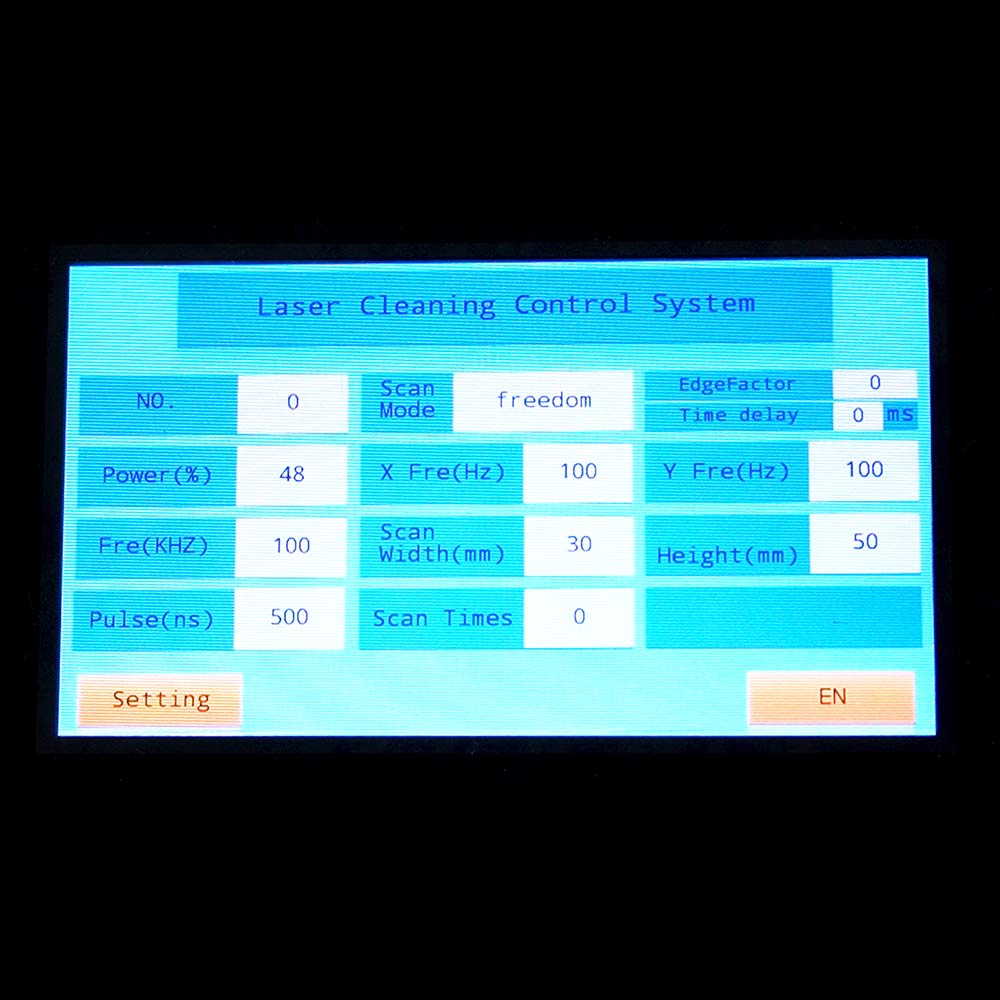

Control System

The system operation is relatively stable, and parameter adjustment is simple and fast.

Meet our products

Not easy to deform

Large welding depth

Red light positioning

Multi angle and multi position

6-axis robot drive

High welding efficiency

High qualification rate

Small welding deformation

Ergonomic design

Simplify process

Integrated cabinet

BWT laser source

Swing welded joint

Control system

Double temperature chiller

Wire feeder (optional)

Integrated cabinet

Mopa pulsed laser source

Swing welded

Control system

Double temperature chiller

Integrated cabinet

Raycus laser source

Swing welded joint

Control system

Double temperature chiller

Contact us

Do you want to learn more about JQ Laser products? Or maybe you have questions about our company? Do not hesitate to contact us via the following contact form.