Introduction

Laser welding has revolutionized the manufacturing industry, enabling precise and efficient joining of materials. Over the years, there have been significant breakthroughs in laser welding machine technology, making the process more accessible, versatile, and productive than ever before. This article explores the advancements in laser welding machines, their benefits, applications, challenges, and the future trends shaping the industry.

Understanding Laser Welding Machine Technology

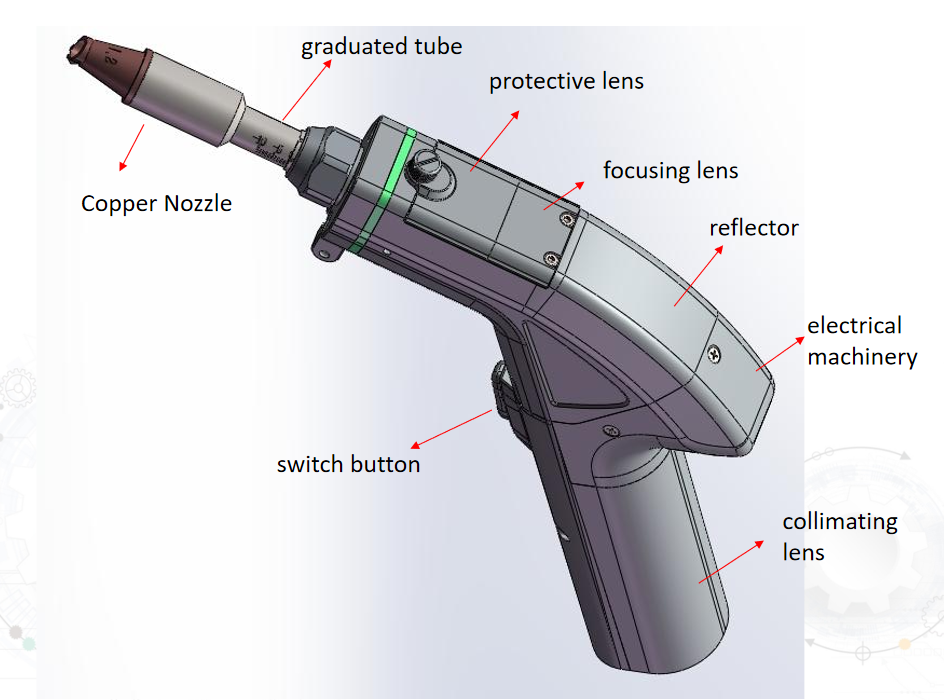

Laser welding machines use highly focused laser beams to melt and fuse materials together. The process involves the use of a laser source, which can be either a solid-state laser, a fiber laser, or a diode laser. The laser generates an intense beam of light that is directed through optics and onto the workpiece, creating a weld joint with minimal heat-affected zones.

Advancements in Laser Welding Machine Technology

3.1. Fiber Laser Technology

Fiber lasers have gained popularity due to their high efficiency and reliability. They offer excellent beam quality, making them suitable for precision welding tasks. Additionally, fiber lasers can be easily integrated into automated systems, further enhancing productivity.

3.2. High-Power Diode Lasers

High-power diode lasers provide robust and continuous output, making them ideal for industrial applications. They are commonly used in high-speed welding processes and are known for their low maintenance requirements.

3.3. Direct Diode Laser Systems

Direct diode lasers are compact and energy-efficient, making them suitable for handheld and portable welding devices. Their direct emission capability eliminates the need for optical fibers, reducing complexity and potential losses.

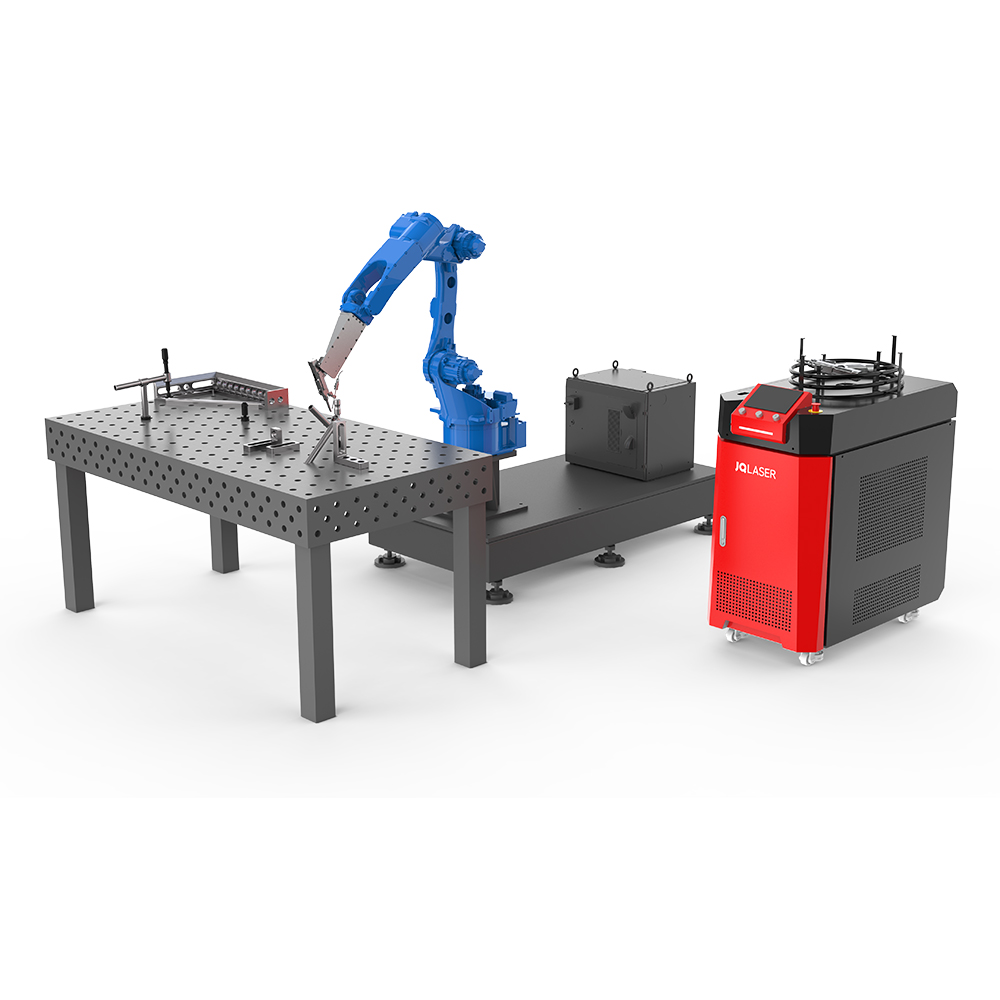

3.4. Automation and Robotics Integration

Modern laser welding machines are often equipped with advanced automation and robotics features. This integration streamlines production, reduces human error, and enables the welding of complex shapes with ease.

3.5. Real-time Process Monitoring

Real-time process monitoring technologies, such as thermal imaging and sensors, ensure the quality and consistency of welds. These systems detect defects and deviations promptly, allowing for immediate adjustments and ensuring optimal weld integrity.

Benefits of Modern Laser Welding Machines

4.1. Precision and Quality

Laser welding offers unmatched precision, producing clean and aesthetically pleasing welds with minimal distortion. This level of accuracy is especially crucial in industries like electronics and medical devices.

4.2. Increased Productivity

Laser welding machines boast high welding speeds and rapid production capabilities, leading to increased productivity and shorter lead times.

4.3. Reduced Energy Consumption

Compared to conventional welding methods, laser welding consumes less energy, contributing to cost savings and environmental sustainability.

4.4. Versatility and Application Range

Laser welding can be applied to a wide range of materials, including metals, plastics, ceramics, and more. It finds applications in diverse industries, from automotive to jewelry making.

Applications of Laser Welding Machines

5.1. Automotive Industry

Laser welding plays a crucial role in the automotive sector, where it is used for joining body panels, chassis components, and even batteries in electric vehicles.

5.2. Aerospace and Aviation

In the aerospace industry, laser welding is employed to manufacture complex aircraft components, ensuring structural integrity and reducing overall weight.

5.3. Electronics Manufacturing

Laser welding is widely used in electronics manufacturing for precise soldering and component assembly, ensuring reliable connections in modern devices.

5.4. Medical Devices

The medical industry benefits from laser welding’s ability to join small and delicate components in medical devices, enabling minimally invasive procedures.

5.5. Jewelry and Artwork

Laser welding has revolutionized jewelry making and artwork creation, allowing artists and craftsmen to achieve intricate designs with ease.

Overcoming Challenges and Limitations

6.1. Material Compatibility

Laser welding may not be suitable for all materials, and certain combinations may require additional pre-treatment or alternate joining methods.

6.2. Initial Investment Costs

While laser welding offers long-term cost benefits, the initial setup costs can be significant, especially for small businesses.

6.3. Skilled Operator Requirement

Operating a laser welding machine requires specialized training, and skilled operators are necessary to ensure optimal results.

6.4. Safety Concerns

Laser welding involves high-intensity light, requiring proper safety measures and protective gear to prevent accidents and exposure.

Future Trends in Laser Welding Machine Technology

7.1. Advancements in Beam Delivery Systems

Ongoing research focuses on improving beam delivery systems, enhancing precision and stability during welding processes.

7.2. Integration of AI and Machine Learning

Artificial intelligence and machine learning are being integrated into laser welding machines to optimize parameters, predict defects, and improve overall efficiency.

7.3. Enhanced Portability and Flexibility

The industry is working towards developing more portable and flexible laser welding systems, catering to various applications and on-site requirements.

7.4. Green Laser Welding Technology

Green laser welding, utilizing shorter wavelengths, shows promise in delivering better results on certain materials, expanding the scope of laser welding applications.

Conclusion

The continuous advancements in laser welding machine technology have pushed the boundaries of manufacturing and fabrication. The precision, productivity, and versatility of laser welding machines have revolutionized various industries, from automotive and aerospace to electronics and jewelry making. As the technology continues to evolve, we can expect even more breakthroughs, driving innovation and shaping the future of manufacturing.

FAQs

9.1. What is the maximum thickness that can be welded using laser technology?

The maximum thickness that can be welded using laser technology depends on the type of material and laser power. In general, laser welding can handle materials up to several millimeters thick.

9.2. Can laser welding replace traditional welding methods entirely?

While laser welding offers numerous advantages, it may not completely replace traditional welding methods, especially for specific applications that require different welding techniques.

9.3. Are there any health hazards associated with laser welding?

Laser welding, like any laser process, poses potential health hazards such as eye injuries and skin burns. Proper safety measures and protective equipment are essential when working with laser welding machines.

9.4. How does laser welding contribute to sustainability efforts?

Laser welding consumes less energy compared to traditional welding methods, contributing to reduced carbon footprint and overall environmental sustainability.

9.5. Can laser welding be used for 3D printing purposes?

Yes, laser welding is used in certain 3D printing technologies, specifically in metal additive manufacturing, to fuse layers of metal powder together and create intricate 3D structures.