Laser welding technology has the advantage of space-time scale. Accurately controlling the

laser energy release process has a great impact on the performance of subsequent welding workpiece. In

this paper, the molecular vibration theory was used to control the laser energy release process and

optimize the laser welding technology. The technology was applied in 304 stainless steel power battery

shell to analyze the forming effect and performance of the workpiece after welding. The test shows that

keeping the laser incident position in the middle during welding can improve the welding quality. The

welding technology of laser energy release process can greatly strengthen the strength and hardness of

the weld between the power battery shell and the top cover, and provides good practical conditions,

which verifies the effectiveness and applicability of the laser welding technology.

Effect

During laser welding, a large number of high-energy photons are emitted when energy is input, which excites molecular vibrations of gases and materials, significantly affecting welding penetration, pores, etc. In the photon absorption stage, energy will be transferred and transmitted. There are a series of physical, chemical and other effects in this process. For the sake of high efficiency of welding and the aesthetics of the 304 stainless steel power battery shell, we have initially explored the role of laser welding technology in 304 stainless steel. The effects on the power battery box are as follows: Under high-precision control, the laser energy is transmitted to the inside of the casing through heat conduction, and the relationship between the laser welding path and the actual required welding path of the casing is obtained.

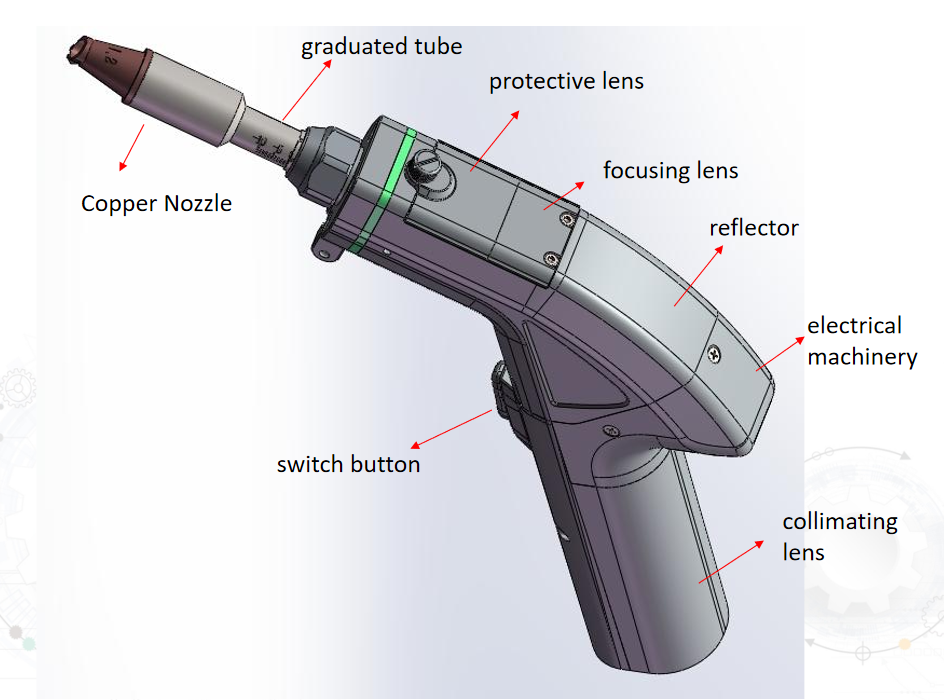

Welding technology introduces molecular vibration theory into laser welding technology. Under the unified control and coordination of components such as lasers and welding work heads, excitation homomorphic photons are emitted to act on alloy materials with high energy density laser energy. A variety of inert gases protect the welding process, effectively prevent the oxidation effect of the weld, control the distance between adjacent pulses acting on the molten pool to become shorter, and the overlapping areas become larger, allowing the weld to penetrate quickly, thus enhancing the mechanics The tensile strength ensures the practicality and durability of power batteries in large-scale power grids.

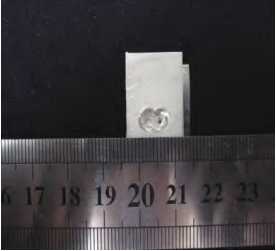

It can be seen that the closer to the center of the weld, the hardness of the weld of each sample becomes larger and larger due to the increase in the melting range. When the distance is farther, the hardness becomes smaller and smaller due to the strengthening and hardening of the material; in this article The welding technology controls the photon release mode of excited atoms and utilizes the linear symmetry mode of carbon dioxide molecules to allow sample C to obtain more energy during the welding process. Therefore, the hardness of the weld is higher and the decrease is smaller.

Conclusion

Laser welding technology has the advantages of penetration depth, welding speed, energy density, etc., but its welding fineness still has certain restrictions and limitations on the applicability of 304 stainless steel power batteries. Therefore, for the 304 stainless steel power battery shell, laser welding can be refined through the application of carbon dioxide molecules and helium gas, combined with molecular vibration theory to control the photon release mode of excited atoms. The experimental results show that the weld penetration values are different under different laser incident positions. Among them, when the laser beam is located at the center of the top cover, the penetration depth is the largest, with an average of 0.482 mm. Fracture occurred only when the tensile strength reached 1873 N, and the tensile strength reached 98 MPa. The maximum hardness of the weld reaches 93 HV, and as the distance increases, the maximum decrease is only 11 HV. This shows that the method studied in this article improves the welding quality to a certain extent. And regarding the shortcomings in the research work, further exploration will be carried out from the following aspects: more test conditions should be added to the experimental link, the actual application environment of power batteries on the grid side should be simulated, and laser welding technology should be improved; welding equipment should be used as the The core establishes a refined operating system, combined with welding detection technology, to observe the welding morphology in real time and better control the welding quality.