The galvanized layer of galvanized sheets not only has good electrical conductivity, but also has excellent protective effects. The good corrosion resistance of galvanized sheets makes them popular in many fields, including construction, light industry, automobiles, agriculture, animal husbandry and fishery, etc. . However, the existence of zinc layer in galvanized sheets makes the welding of galvanized sheets very limited. During the welding of galvanized sheets, there is a very big difference in the physical properties of the galvanized layer and the internal steel (the melting point of steel is 1300°C, the boiling point is 2861°C, the melting point of the galvanized layer is 420°C, the boiling point is 908°C) and it is easy to produce pores and spatter. , The gap is too large, the shape is poor after welding, etc. Laser welding is a high-energy beam welding technology. It has the characteristics of high energy density, small thermal deformation, large weld depth-to-width ratio, fast welding speed, and small loss of galvanized layer. It is very suitable for precision welding. Laser wire filler welding can effectively suppress the generation of pores and gap problems in galvanized sheets during splicing. Laser oscillating filler welding is a new type of laser welding method. It has been successfully applied in tailor-made plate welding and improving the tolerance of weldment assembly gaps. However, there is little research on the welding of galvanized sheets by oscillating filler. mentioned. This article takes 1.5mm galvanized sheet as the research object, focusing on the optimal process parameters and morphology of the galvanized sheet under different gaps.

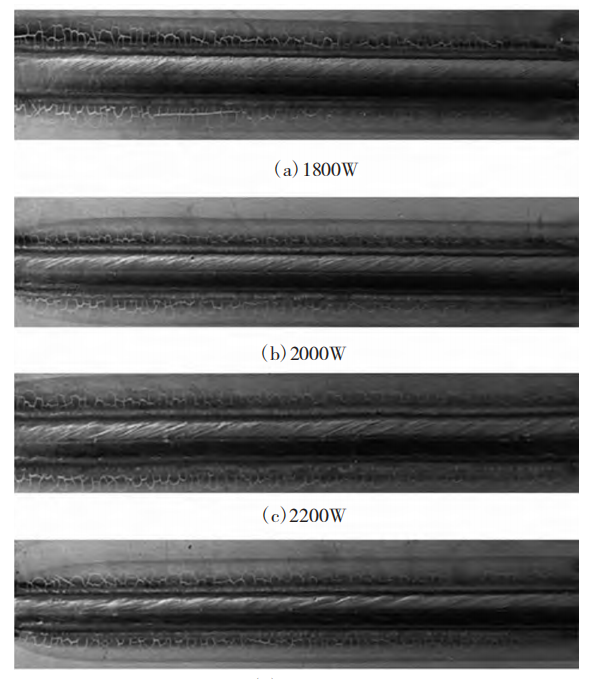

The influence of different powers on the forming and pores of galvanized sheets.

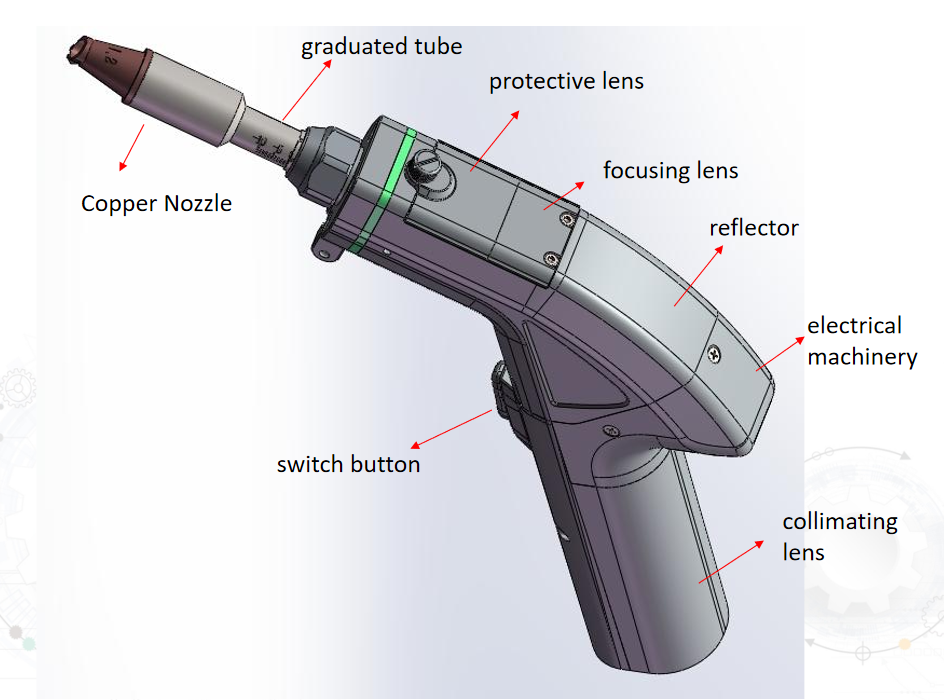

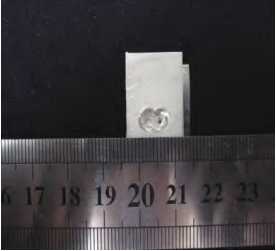

The gap between the sheets was fixed at 0.3mm and the wire feed speed was 25mm/s. Experiments were conducted with different welding powers (1800W, 2000W, 2200W, 2400W). Figure 1 shows a comparison of surface morphology under different welding powers. The higher the welding power of galvanized sheets, the swinging laser beam continuously stirs the molten pool, the flow rate of the molten pool increases, and the deeper the molten pool becomes. From the figure, we can see that when the power reaches about 2400W, the laser molten pool is too deep and there are obvious undercuts. When the power reaches about 2000W, the power and welding wire are in a stable state, the shape is full, and there are no obvious pores on the surface.

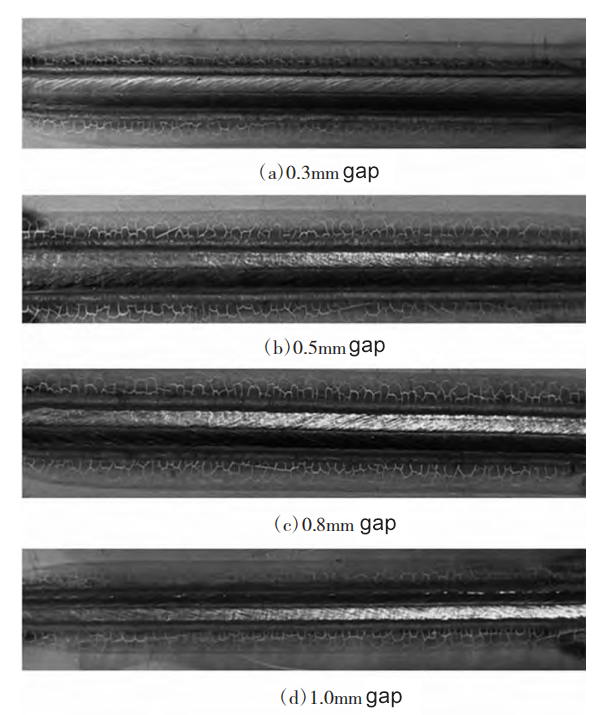

The influence of different gaps on the forming and pores of galvanized sheets.

The laser power is fixed at 2000W, the wire feeding speed is 25mm/s, and the splicing gaps (0.3mm, 0.5mm, 0.8mm, 1.0mm) are used for experiments. In the picture is a comparison chart of the surface morphology under different splicing gaps. When other factors remain unchanged during laser swing filler wire welding, the original full and smooth shape will become larger as the gap continues to increase. The welding wire cannot fully cover the welding surface of the galvanized plate, resulting in a poor shape. The protrusion of the welding surface gradually decreases, and when the gap reaches 1.0mm, undercut and depression appear.

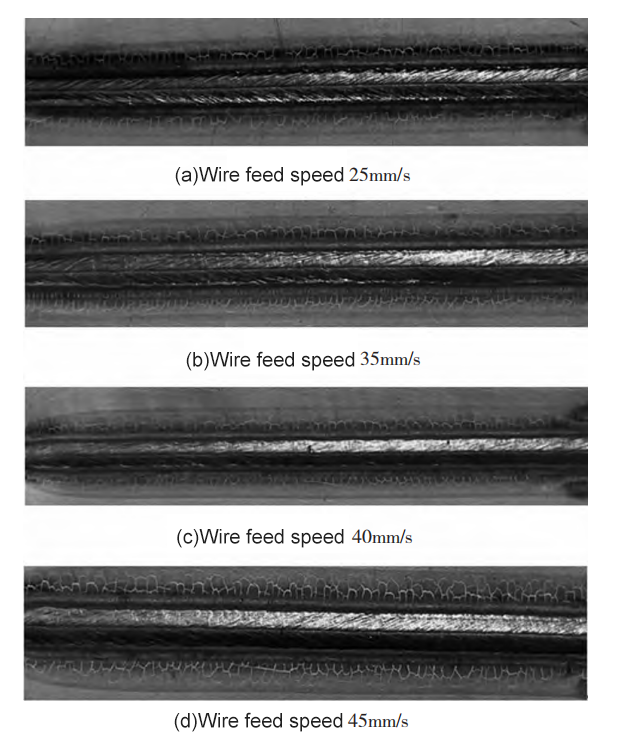

The influence of different wire feeding speeds on the formation and pores of galvanized sheets.

The fixed gap is 0.8mm, the laser power is 2200W, and experiments are conducted with different wire feeding speeds (25mm/s, 30 mm/s, 35 mm/s, 45 mm/s). Figure 3 is a comparison chart of the surface topography under different splicing gaps. When the power and splicing gap are fixed, the wire feeding speed is slow, the welding material is ugly, and there are obvious depressions, which cannot achieve the advantages of laser wire filling welding; increase the wire feeding speed, It melts with the base metal during welding and forms a well-formed weld without pores after welding.

Conclusion

When laser swing filler wire welding is at 2000~2200W, the 1.5mm galvanized sheet will have a stable state, and it will not change much due to changes in wire feed speed. (2) The gap in laser swing filler welding gradually becomes larger. The more welding wire needs to be melted in, the amount of welding wire will affect the forming effect. Too much welding wire may cause accumulation and cannot be melted, and too little welding wire may cause depressions. (3) When the power, gap, and wire feeding speed match, the aspect ratio can reach 85% to 95%. Laser swing filler wire welding of galvanized sheets has good formation, high penetration, strong welding strength, and no dents. It can reduce the subsequent processing and polishing time, or even eliminate the need for processing. Through the metallographic diagram, we can clearly see that the fatal weakness of galvanized sheets, the problem of pores, has been greatly improved and is basically pore-free.