Laser welding technology has revolutionized various industries by providing efficient and precise joining solutions. Over the years, advancements in laser welding have paved the way for improved productivity, reduced costs, and enhanced quality in manufacturing processes. In this article, we will explore the future trends in laser welding technology and how they are set to shape the industry.

Table of Contents

- Introduction

- Increased Power and Speed of Laser Welding

- Integration of Artificial Intelligence

- Fiber and Disk Lasers

- Hybrid Welding Technologies

- Enhanced Weld Monitoring and Quality Control

- Industry-Specific Applications

- Advancements in Welding Materials

- Compact and Portable Laser Welding Systems

- Environmental Sustainability

- Conclusion

- FAQs

Introduction

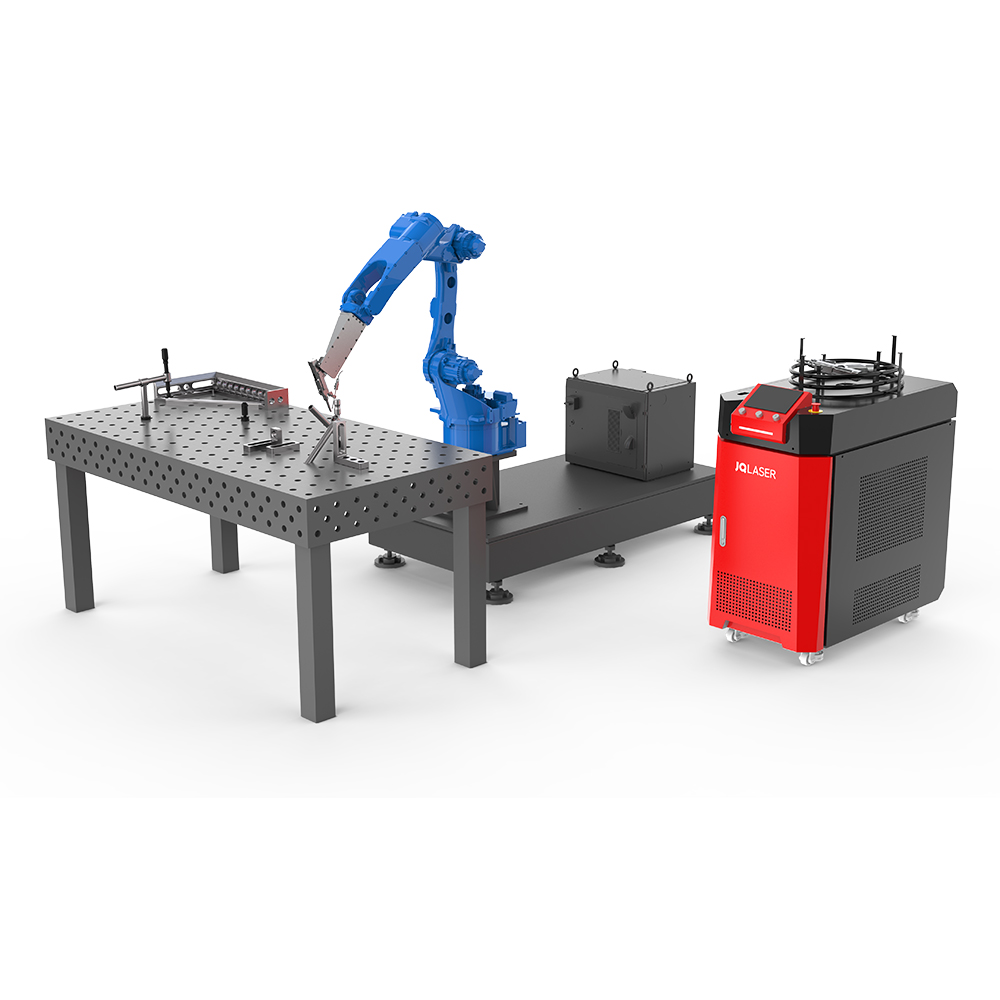

Laser welding has gained significant popularity in industries such as automotive, aerospace, electronics, and medical devices due to its high precision and speed. As technology continues to evolve, several trends are emerging that will further enhance the capabilities of laser welding systems.

Increased Power and Speed of Laser Welding

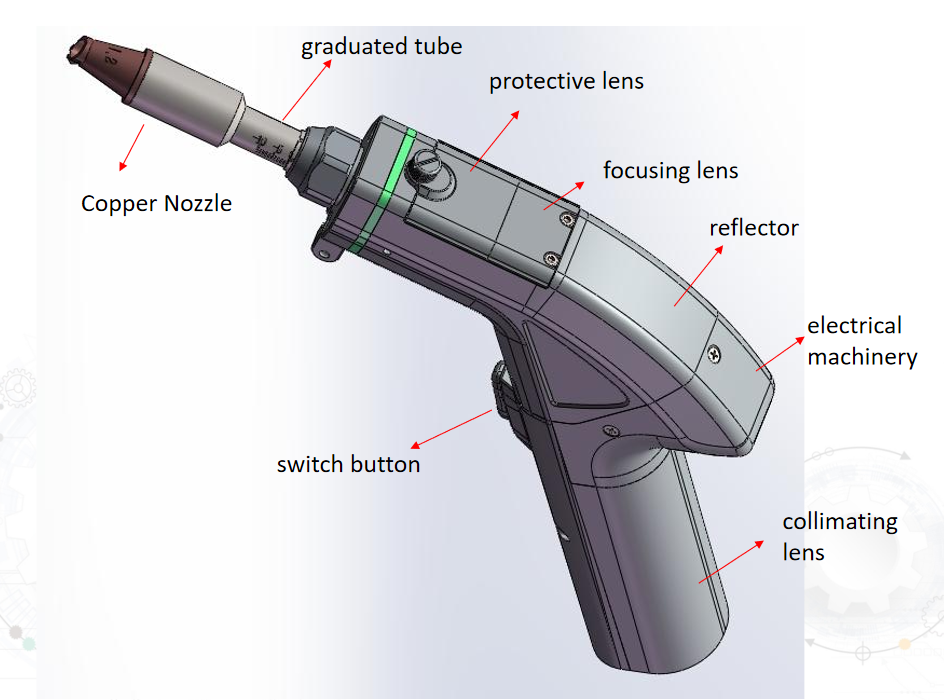

One of the key future trends in laser welding technology is the continuous increase in power and speed. Higher power lasers allow for deeper penetration, enabling the welding of thicker materials. Faster processing speeds result in shorter cycle times and increased productivity. With advancements in laser sources and beam delivery systems, laser welding will become even more efficient, enabling manufacturers to meet growing demands.

Integration of Artificial Intelligence

Artificial Intelligence (AI) is revolutionizing various industries, and laser welding is no exception. AI algorithms can analyze real-time welding data and make adjustments to optimize the welding process. By monitoring parameters such as power, speed, and beam quality, AI-powered systems can detect and correct anomalies, leading to improved weld quality and reduced defects. Integration of AI in laser welding technology will pave the way for autonomous welding systems capable of self-adjustment and continuous improvement.

Fiber and Disk Lasers

Fiber and disk lasers are emerging as the next generation of laser sources for welding applications. These lasers offer advantages such as high beam quality, excellent power efficiency, and compact size. Fiber lasers are highly flexible, enabling precise control over the beam profile, while disk lasers provide high average power output. The adoption of fiber and disk lasers in laser welding systems will enhance the overall performance and reliability of the process.

Hybrid Welding Technologies

Hybrid welding technologies combine laser welding with other complementary joining methods, such as arc welding or electron beam welding. This hybrid approach leverages the strengths of each process to achieve superior results. For example, laser-arc hybrid welding combines the deep penetration capability of lasers with the high deposition rate of arc welding, resulting in faster and more efficient welds. The integration of different welding technologies will lead to innovative solutions for complex manufacturing requirements.

Enhanced Weld Monitoring and Quality Control

In the future, laser welding systems will incorporate advanced monitoring and quality control features. Real-time monitoring of welding parameters, such as temperature, weld pool dynamics, and joint fit-up, will enable immediate feedback and adjustment during the welding process. This level of control ensures consistent weld quality and reduces the likelihood of defects. Additionally, automated inspection systems utilizing machine vision and machine learning algorithms will further enhance quality control measures.

Industry-Specific Applications

As laser welding technology continues to evolve, industry-specific applications will emerge. For instance, in the automotive industry, laser welding is being used for lightweight construction, joining dissimilar materials, and battery manufacturing. In the medical field, laser welding enables the precise assembly of medical devices and implants. The versatility of laser welding makes it suitable for various industries, and future advancements will unlock new possibilities.

Advancements in Welding Materials

The development of new welding materials will play a crucial role in the future of laser welding technology. As industries push the boundaries of material performance and characteristics, laser welding must adapt to accommodate these advancements. Laser welding techniques will be refined to join dissimilar materials, such as lightweight alloys, composites, and dissimilar metals. Moreover, advancements in filler wire and powder materials will further enhance the welding process.

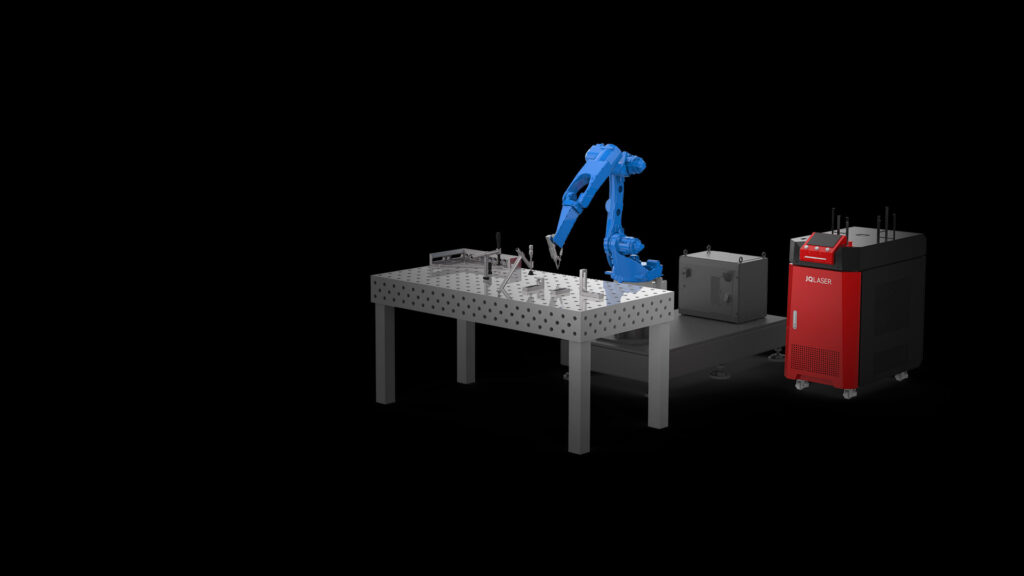

Compact and Portable Laser Welding Systems

The demand for flexibility and portability in manufacturing processes is driving the development of compact and portable laser welding systems. These systems offer the convenience of on-site repairs, reducing downtime and transportation costs. Compact laser welding systems will find applications in industries such as construction, shipbuilding, and maintenance services, where mobility is crucial.

Environmental Sustainability

Sustainable manufacturing practices are becoming increasingly important, and laser welding technology contributes to environmental sustainability. Laser welding generates minimal waste, as it is a non-contact process that requires no consumables. Furthermore, laser welding produces precise and controlled heat input, reducing energy consumption and minimizing the carbon footprint. As the focus on sustainability grows, laser welding will continue to be an eco-friendly solution for joining applications.

Conclusion

The future of laser welding technology is promising, with advancements in power, speed, artificial intelligence, laser sources, and quality control. These trends will enable manufacturers to achieve higher productivity, improved weld quality, and greater flexibility in their manufacturing processes. Laser welding’s versatility and precision make it an indispensable tool across various industries, and the future developments will further enhance its capabilities.

FAQs

- Q: What industries benefit from laser welding technology? A: Laser welding technology benefits industries such as automotive, aerospace, electronics, and medical devices.

- Q: How does artificial intelligence enhance laser welding? A: Artificial intelligence in laser welding enables real-time monitoring, adjustment, and optimization of welding processes, leading to improved quality and reduced defects.

- Q: What are the advantages of fiber and disk lasers in welding? A: Fiber and disk lasers offer high beam quality, power efficiency, and compact size, enhancing the performance and reliability of laser welding systems.

- Q: How does hybrid welding technology work? A: Hybrid welding technology combines laser welding with other methods, such as arc welding or electron beam welding, to achieve superior results by leveraging the strengths of each process.

- Q: How does laser welding contribute to environmental sustainability? A: Laser welding generates minimal waste, requires no consumables, and reduces energy consumption, making it an eco-friendly solution for joining applications.