1. Introduction

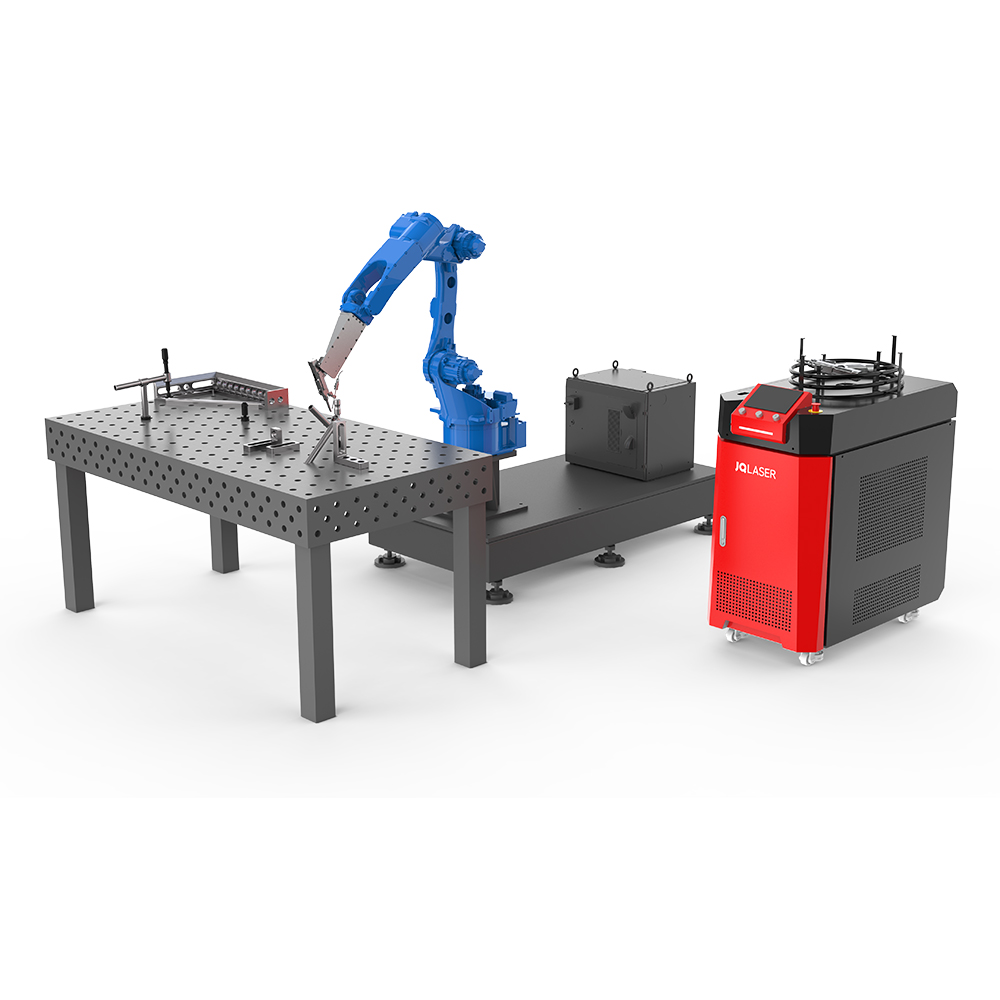

Laser welding is a process that utilizes a highly concentrated laser beam to melt and fuse metal components together. It is widely employed in industries such as automotive, aerospace, electronics, and medical devices due to its precision and speed. However, certain challenges can arise during laser welding, leading to suboptimal results. Understanding and troubleshooting these issues is crucial for ensuring successful welds and maintaining the integrity of the final product.

2. Insufficient Penetration

Insufficient penetration occurs when the laser beam fails to penetrate through the entire thickness of the material being welded. This can result from inadequate power levels, inappropriate focus position, or improper travel speed. To troubleshoot this issue, adjustments in power settings, focal position, or travel speed should be made to achieve sufficient penetration depth.

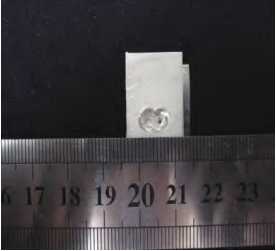

3. Porosity Formation

Porosity, characterized by the presence of small voids within the weld, can weaken the joint and compromise its integrity. It can be caused by several factors, such as gas entrapment, improper shielding gas flow, or surface contamination. To address porosity formation, ensuring proper gas shielding, thorough material cleaning, and optimizing welding parameters are essential.

4. Weld Cracking

Weld cracking is a critical issue that can occur due to high thermal stresses or material incompatibility. It can manifest as hot cracking or cold cracking, depending on the welding conditions. To prevent weld cracking, it is crucial to control the heat input, utilize suitable filler materials, and ensure proper preheating or post-weld heat treatment when necessary.

5. Keyhole Collapse

Keyhole collapse refers to the sudden collapse or closure of the vapor-filled void, known as the keyhole, during laser welding. It can lead to an irregular weld shape and insufficient penetration. Keyhole collapse is often caused by instabilities in the welding process or inappropriate laser parameters. Adjusting the laser power, maintaining consistent laser beam delivery, and optimizing the focal position can help overcome this issue.

6. Excessive Spatter

Excessive spatter, the ejection of molten metal particles during welding, can result in poor weld quality and contamination of the surrounding area. Spatter formation can be attributed to factors such as high power density, improper shielding gas, or surface impurities. To reduce spatter, optimizing welding parameters, ensuring adequate shielding gas flow, and employing proper surface preparation techniques are necessary.

7. Thermal Distortion

Thermal distortion occurs when localized heating and subsequent cooling during the welding process cause the material to deform or warp. This can lead to dimensional inaccuracies and misalignment of welded components. To minimize thermal distortion, preheating, post-weld heat treatment, or the use of fixturing techniques can be employed to control the heat distribution and mitigate its effects.

8. Inconsistent Weld Quality

Inconsistent weld quality can be observed as variations in penetration depth, bead shape, or weld width along the joint. It can result from factors like inconsistent laser beam delivery, unstable power supply, or material inhomogeneities. Ensuring proper beam alignment, optimizing power stability, and selecting suitable welding parameters can help achieve consistent weld quality.

9. Beam Misalignment

Beam misalignment occurs when the laser beam is not aligned precisely with the joint or the desired welding path. This can lead to incomplete fusion or uneven weld formation. Proper alignment of the laser beam using alignment tools, regular maintenance of optical components, and real-time monitoring can help avoid beam misalignment issues.

10. Material Compatibility Issues

Material compatibility issues arise when the materials being welded have different thermal properties, melting points, or chemical compositions. Mismatched materials can result in welding difficulties, such as cracking, porosity, or poor joint strength. It is essential to consider material compatibility during the design stage and select appropriate welding techniques or filler materials to ensure compatibility and optimize weld quality.

11. Contamination

Contamination of the weld zone can occur due to the presence of dirt, oil, rust, or other foreign substances on the surface of the materials. These contaminants can hinder the formation of a sound weld and lead to defects. Thorough cleaning of the welding surfaces using appropriate solvents or mechanical methods is necessary to prevent contamination-related issues.

12. Inadequate Shielding Gas

Inadequate shielding gas coverage can result in oxidation of the weld zone, leading to poor weld quality and reduced mechanical properties. Insufficient gas flow rate, improper nozzle-to-work distance, or gas leakage can contribute to this issue. Ensuring proper gas flow, correct positioning of the shielding gas nozzle, and regular inspection of gas supply systems are essential for effective shielding and weld quality.

13. Power Instability

Power instability during laser welding can cause fluctuations in the laser output, resulting in inconsistent weld quality and potential defects. Power instability can arise from power source issues, electrical interference, or inadequate cooling of laser components. Regular maintenance and calibration of the power source, ensuring stable electrical supply, and optimizing cooling systems can help stabilize the power output.

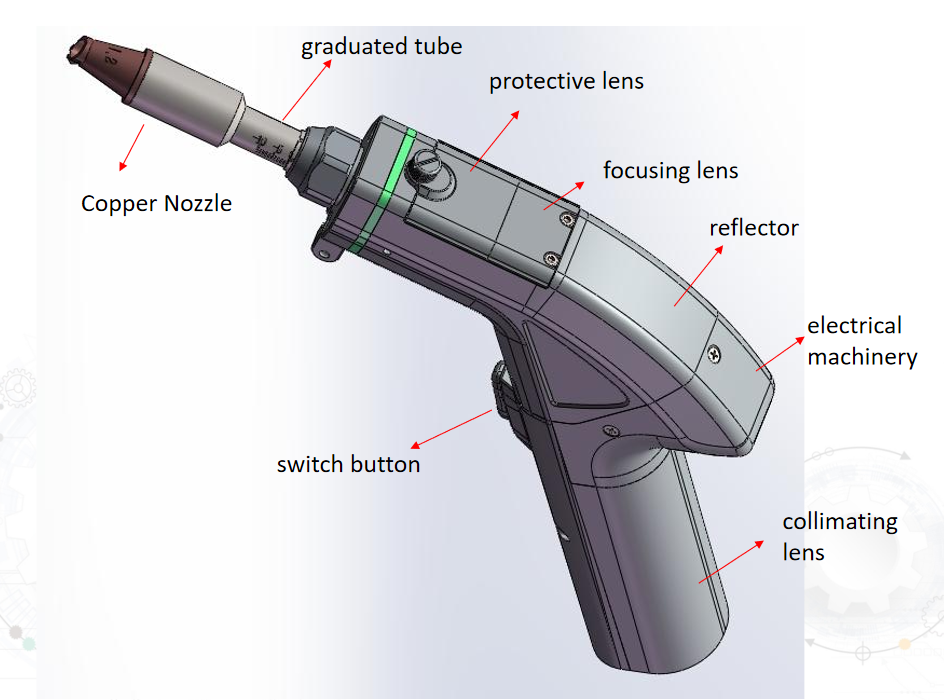

14. Focusing Issues

Focusing issues occur when the laser beam is not properly focused on the welding surface, leading to variations in weld quality and penetration depth. This can be caused by lens contamination, misalignment of optical components, or incorrect focal position. Regular cleaning and maintenance of optical components, precise adjustment of the focal length, and monitoring beam quality can address focusing issues effectively.

15. Conclusion

In conclusion, laser welding is a versatile and efficient technique, but it can encounter various challenges during the welding process. By understanding the common issues and employing appropriate troubleshooting techniques, welders can overcome these obstacles and achieve high-quality welds. It is essential to optimize welding parameters, ensure material compatibility, maintain proper cleanliness, and monitor the welding process closely to minimize defects and achieve reliable and durable weld joints.

FAQs (Frequently Asked Questions)

- Q: Can laser welding be used for all types of metals? A: Laser welding can be used for a wide range of metals, including stainless steel, aluminum, titanium, and copper. However, the suitability of laser welding for a specific metal depends on its thermal properties and reflectivity.

- Q: How can I prevent porosity formation in laser welding? A: To preventporosity formation in laser welding, ensure proper shielding gas flow, clean the welding surfaces thoroughly, and optimize welding parameters such as power levels and travel speed.

- Q: What is the advantage of laser welding over traditional welding methods? A: Laser welding offers several advantages over traditional welding methods, including higher precision, faster processing times, reduced heat input, and minimal distortion of the surrounding material.

- Q: How can I troubleshoot inconsistent weld quality in laser welding? A: To troubleshoot inconsistent weld quality, check for beam misalignment, stabilize the power source, and optimize welding parameters such as laser beam delivery and material compatibility.

- Q: Can laser welding cause thermal distortion in the welded components? A: Yes, laser welding can cause thermal distortion due to localized heating and subsequent cooling. To minimize thermal distortion, preheating, post-weld heat treatment, or the use of fixturing techniques can be employed.

- Q: What is the role of shielding gas in laser welding? A: Shielding gas in laser welding helps protect the weld zone from oxidation and contamination, ensuring a clean and sound weld. It also helps to maintain stable weld quality and mechanical properties.